Changing the Game for Commercial Water Softening Systems

Ever since Clack Corporation came out with their commercial water softener valves (and when I say "commercial," I mean 1.5", 2" and 3" valves), there has been constant discussion about which valve is the best in water conditioning circles - Clack or Fleck? Clack has made great inroads into Fleck's commercial business and it is difficult for me to say what is the most popular system today.

There is no doubt that Clack and Fleck both make good systems. Fleck has been manufacturing Commercial Water Softener control valves for many years. They may have started in the late 1960's or early 1970's and they were THE BRAND until the late 2000's when Clack rolled out their 1.5", 2" and 3" Valves. Now, (it seems to me) that they have half of the market. Neither company should get too comfortable because there is a third company which has entered the commercial water softener realm and while they do not have a complete line (yet), what they have is revolutionizing the commercial water softening industry.

That company is Chandler Systems, located in Ashland, Ohio and quietly (or not so quietly) they have become a force to be reckoned with in the water conditioning industry. Currently, they have 1", 1.25", and 1.5" Valves with plans for more, but what makes them dramatically different is their use of cutting-edge electronics. This enables them to have smaller, more powerful, dramatically easier-to-install systems that provide a level of control no one in the industry currently has.

By way of introduction, with over 35 years in the industry, Chandler Systems is a premier manufacturer of water treatment products, holding over 40 patents in water treatment, motor control, and electronic systems. The founder, Bill Chandler, started manufacturing water treatment products in 1980, and in 1993, began production of electrical and electronic products.

The following things are of paramount consideration:

- Initial Cost (it's always about the money)

- Floor Space (floor space is always at a premium - if you can conserve space, it's a huge plus)

- Ease of Installation (not having to plumb in additional meters or MAV valves and run wiring is a huge plus)

- Ease of Programming (in multi-tank systems - you may have to climb a ladder or program each control)

- Repair Costs (multiple piston and parts are expensive to replace)

- System monitoring & site protection (remote monitoring is standard along with Leak Protection)

It's no longer a question as to whether you want all of the above features and benefits.

The question now is "Why would you not want all of the above features and benefits?"

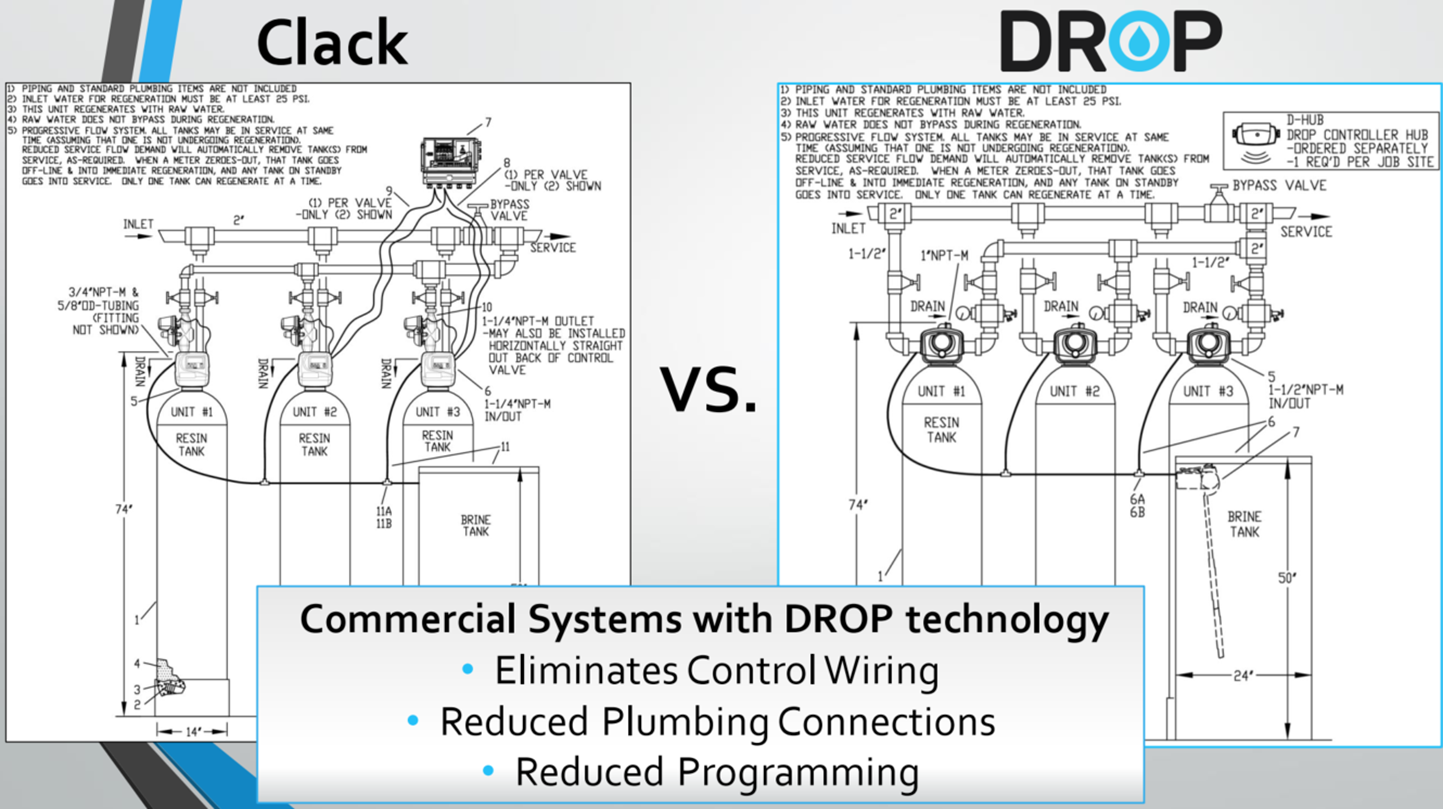

As an example, let's look at a couple of systems: System 1 is a Clack 1.5" progressive flow triplex system, while System 2 is a CSI DROP® progressive flow triplex system.

| System 1: Clack 1.5" Triplex | System 2: CSI DROP® 1.5" Triplex |

|---|---|

| Three Tanks | Three Tanks |

| Three Meters | Three Valves |

| Three Valves | Wireless DROP® Hub |

| Three MAV (No hard water bypass) Valves | |

| System Controller | |

| Three Communication Cables |

Just to be clear, let me visually show what you will need to install either system:

System 1: Clack 1.5" Progressive Triplex

System 2: CSI DRO® 1.5" Progressive Triplex

Now, here are the components that you need with a CSI DROP® Three tank progressive-flow system:

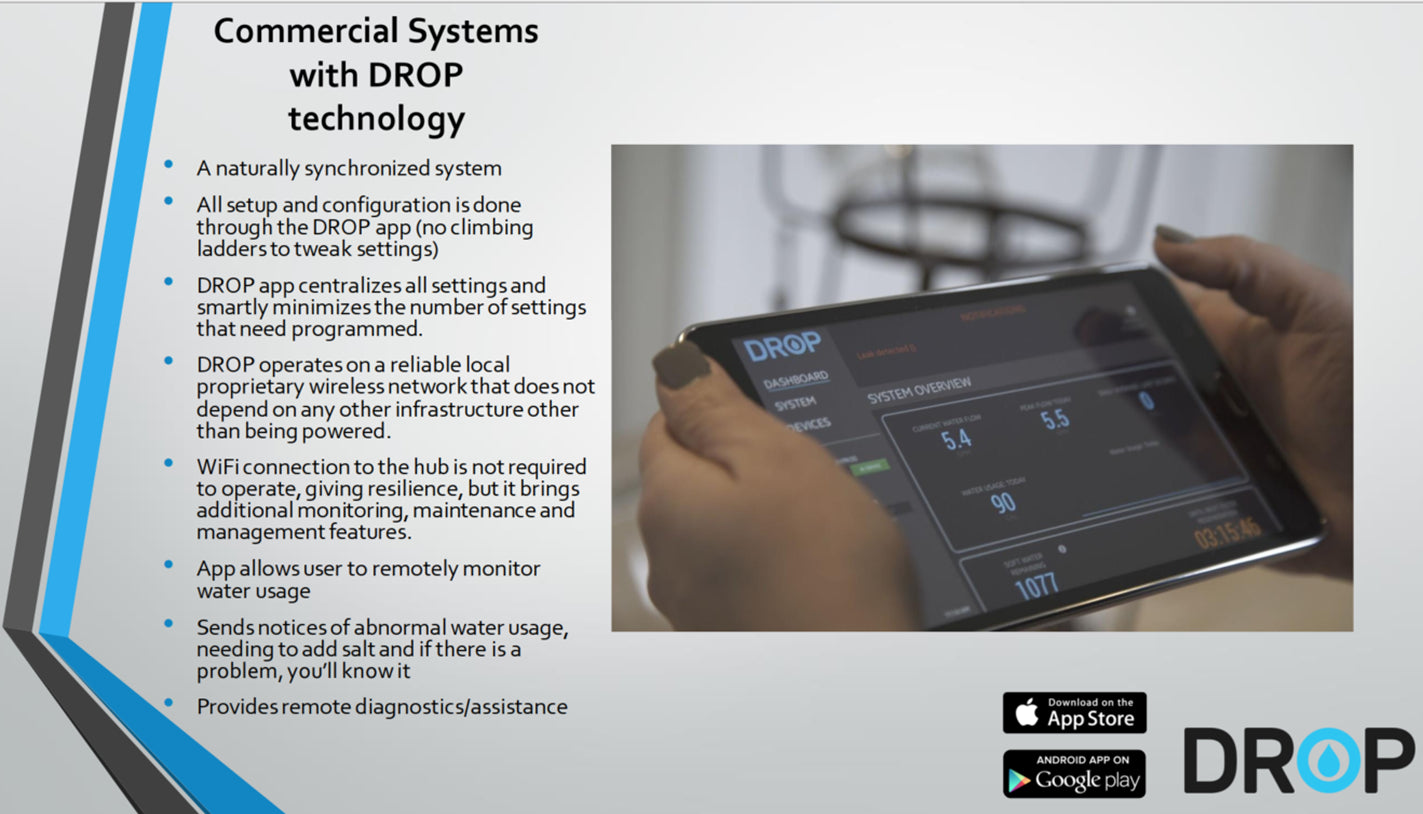

With the CSI DROP® 1.5" Valves, no MAV is required. Plumbing in three MAV Valves is a time-consuming process that adds several hours to the installation time. Bypass is automatic, so no MAV is required. The meter is built-in and can easily be externally disassembled to remove any debris that could clog the meter in a matter of minutes. No wiring is necessary. The DROP® Connect Hub communicates with the DROP® Control Valves via Bluetooth or WiFi and is programmed with a smart phone, i-pad or other device.

No wiring to run, no MAV valves to plumb in, no external meters. The new CSI DROP® System is about as plug n play as it gets. The bottom line is that whoever owns this system is going to pay less for it because they are fewer parts (when was the last time someone said "Can you make this with more parts?") Also, there is the ease of upgrading.

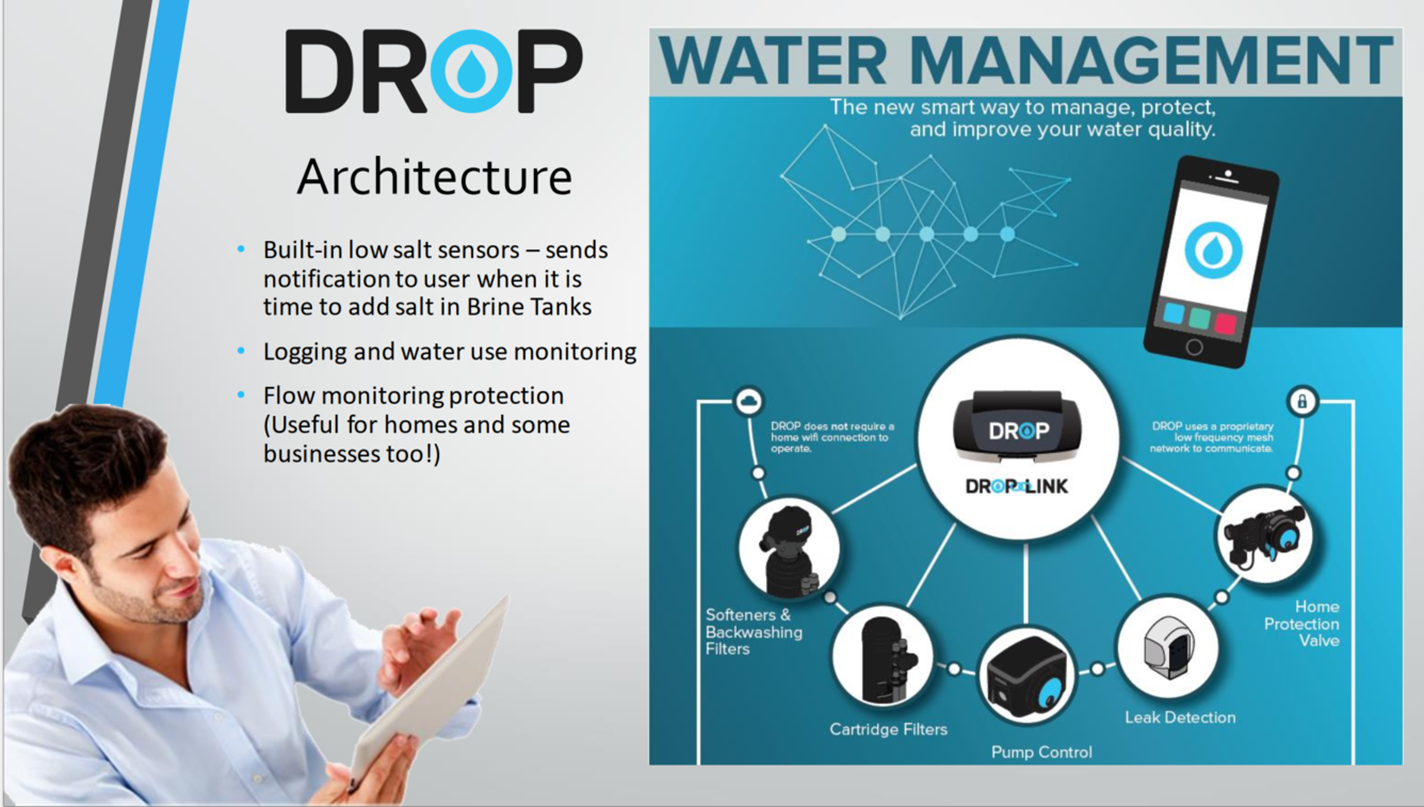

. . . and I haven't even mentioned the Water Management Feature which is the best in the business. No other system comes close to doing what the DROP® Water Management System does. You can use part or all other DROP® Water Management system. Many businesses use the salt notification and leak-detection component which can save you from a flood. That's just icing on the cake. No other commercial water softener system has all of that.

Not only does a DROP® System work well with Progressive Flow, but also think about it with a 2" Twin System with ten (10) cubic feet of resin in each tank. Peak flow is approximately 100 GPM when one system is in regeneration. Now, instead of using (2) 24" x 72" resin tanks, with DROP®, you can use (3) 18" x 65" resin tanks. Each tank will deliver 50 GPM, so even when one tank is in regeneration, you still have 100 GPM. It helps eliminate channeling and promotes better salt efficiency. DROP® is dramatically easier to install, takes up about the same space, but can be closer to the wall, and the best thing is that the overall installed cost can be about $4,000 to $6,000 less than a Clack or a Fleck 2900 system.

In Conclusion

DROP® Technology by CSI carries the day.

- It costs less

- It's easier to install

- It's easier to monitor and control

- It tells you when to add salt

- You can monitor it remotely

- It prevents floods in your business (if you elect to use that feature)

US Water Systems is proud to be a Distributor for Chandler Systems and we look forward to providing you with the finest water conditioning system available on Planet Earth today. If you have questions, please call one of our Certified Water Specialists or Master Water Specialists at 800-608-8792.

Written by Mark Timmons, Master Water Specialist, aka/ The Water Doctor. Mark is the President of US Water Systems, Inc. a water products manufacturer based in Indianapolis, Indiana. 2022 marks his 50th year in the water quality industry.

Leave a comment

Please note, comments need to be approved before they are published.