SIGN UP FOR OUR NEWSLETTER

Receive our latest updates about our products & promotions.

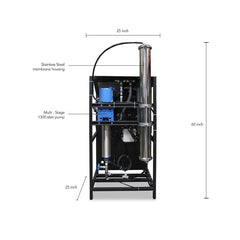

The Defender is a customizable commercial RO System that was designed to be durable, sustainable, economical, and eco-friendly. It is built in the USA specifically with commercial and industrial applications in mind. This system ranks high in dependability and is easy to service and maintain thanks to the highest quality of parts and components such as stainless steel housings, industrial pumps, and reinforced fittings. It was designed for a wide range of flow requirements for various industries such as:

Hydroponics, Brewing, Distilling, Food Service, Pulp and Paper, Pharmaceutical Manufacturing, Textile Manufacturing, and Hospitality

Free standard shipping on most products over $199.

Free shipping on most products over $199. Freight orders excluded. Speak to a water expert for more details.

Our Master Water Specialists and Certified Water Specialists review your water analysis and address your specific water problems. WE then design a system that we guarantee will solve your water problem(s) and back it with our One-Year Money Back Promise (Guarantee).

It all starts with a Laboratory Test of your water. Then, our Master Water Specialists and Certified Water Specialists will review the results of your water analysis and scientifically discuss the best way to treat your water, provide on estimate of how to do that, and then we provide you a One-Year Guarantee of Satisfaction. It's our Promise to You that our system will do what we say or we will give you your money back*

Designed to be sustainable, economical, and eco-friendly, the Defender Commercial RO System is a commercial-grade RO system that is built upon our principles of reliability and dependability. US Water Systems proudly manufactures this system here, in the USA. It features 300 series stainless steel for both its membrane housings and pump, giving it 3 times the longevity when compared to systems sold by competitors. It was designed for, and has functioned in the following industries:

A reverse osmosis system with proper pre-treatment will last 15-20 years, while one without proper pre-treatment may be ruined in a few months. Our Defender RO System is a Plug & Play, Turnkey System for all water supplies, it has two standard pretreatment options but can be customized. Call us for more details - (800) 608-8792

Made for heavy-duty commercial applications, the Bodyguard High-Flow Chemical Removal Filter is designed to provide the highest performance at the lowest maintenance cost. This filter uses premium Coconut Shell Granular Activated Carbon and Catalytic Carbon rated at 5 years or 1,000,000 gallons to remove chlorine, chloramine, and a plethora of chemicals and pesticides

Made for heavy-duty commercial applications, the Bodyguard High-Flow Chemical Removal Filter is designed to provide the highest performance at the lowest maintenance cost. This filter uses premium Coconut Shell Granular Activated Carbon and Catalytic Carbon rated at 5 years or 1,000,000 gallons to remove chlorine, chloramine, and a plethora of chemicals and pesticides

At US Water Systems we realize that effective water treatment isn't done using a one size fits all approach. That why we have a team of Water Treatment Specialists that can assist you in building a custom system to address your particular water problems.

Permeate flush is an option for our RO systems that can provide a membrane flush directly after shutdown. This flush option is called Permeate Flush because it uses clean water produced by the RO system (permeate or product water) to flush the membranes after shutdown. This is extremely effective when membrane life is going to be a problem. In cases where the dissolved solids of the feed water are elevated this is crucial to membrane life. This may not always be the total dissolved solids (TDS).

In some cases, one particular element such as silica is elevated, and permeate flush is used to make sure it is flushed from the membrane after shutdown. If concentrated solids are left in the membrane housings after shutdown they can precipitate (fall out) from the solution. When this happens the solids remain in the membrane housings until the RO system starts up again. This causes them to be pushed into the membrane instead of flushed as they would be during operation. The membranes eventually become clogged with these solids reducing the lifespan.

A Green Solution

Commercial Pump And Motor

Panel-Mount

5 Micron Magna Pre-Filter

Stainless Steel Membrane Housing

Highest Rejection Rates

Defender Controller With TDS Meter

Best Warranty In The Business

Very light duty pump for intermittent applications. Maybe something you would apply to an under-sink RO

Light duty pump for small RO systems where continual operation is not critical, not for heavy duty operations

Engineered to operate continuously for long periods of time. A True Commercial Pump that you can count on

| Model | DFROM-2000 | DFROM-4000 | DFROM-6000 | DFROM-8000 | DFROM-12000 | DFROM-16000 |

|---|---|---|---|---|---|---|

| Configuration | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass |

| Feed Water Source | City or Well Water | City or Well Water | City or Well Water | City or Well Water | City or Well Water | City or Well Water |

| Standard Recovery Rate | 30% | 48% | 53% | 62% | 62% | 67% |

| Recovery with Concentrate Recycle | Up to 80% | |||||

| Vessels | DFROM-2000 | DFROM-4000 | DFROM-6000 | DFROM-8000 | DFROM-12000 | DFROM-16000 |

| Vessel Array | 1 | 1:1 | 1:1:1 | 1:1:1:1 | 2:2:2 | 2:2:2:2 |

| Vessel Quantity | 1 | 2 | 3 | 4 | 6 | 8 |

| Rejection and Flow Rates | DFROM-2000 | DFROM-4000 | DFROM-6000 | DFROM-8000 | DFROM-12000 | DFROM-16000 |

| Nominal Salt Rejection % | 98.5 | 98.5 | 98.5 | 98.5 | 98.5 | 98.5 |

| Permeate Flow* gpm (lpm) | 1.38 (5.22) | 2.78 (10.52) | 4.16 (15.80) | 5.56 (21.13) | 8.33 (31.67) | 11.1 (42.22) |

| Minimum Feed Flow gpm (lpm) | 2.35 (8.89) | 7.00 (26.50) | 7.16 (27.20) | 8.56 (32.53) | 15.56 (59.13) | 17.1 (64.98) |

| Maximum Feed Flow gpm (lpm) | 6.00 (22.70) | 9.00 (34.07) | 14.00 (53.00) | 14.00 (53.00) | 18.00 (68.4) | 20.00 (76.00) |

| Minimum Concentrate Flow gpm (lpm) | 3.00 (11.36) | 3.00 (11.36) | 3.00 (11.36) | 3.00 (11.36) | 6.00 (22.8) | 6.00 (22.8) |

| Pumps | DFROM-2000 | DFROM-4000 | DFROM-6000 | DFROM-8000 | DFROM-12000 | DFROM-16000 |

| Pump Type | Multi-Stage | Multi-Stage | Multi-Stage | Multi-Stage | Multi-Stage | Multi-Stage |

| Motor HP (kw) | 1.5 (1.10) | 1.5 (1.10) | 1.5 (1.10) | 1.5 (1.10) | 3.0 (2.24) | 3.0 (2.24) |

| RPM @ 60 (50Hz) | 3450 (2900) | |||||

| Connections | ||||||

| Feed inch | 1" FNPT | |||||

| Permeate Inch | 1/2" Tubing | |||||

| Concentrate Inch | 1/2" Tubing | |||||

| Electrical | ||||||

| Voltage | 220V 60Hz 1PH ONLY | |||||

| Voltage Amp Draw | 8.3 | |||||

| Membranes | DFROM-2000 | DFROM-4000 | DFROM-6000 | DFROM-8000 | DFROM-12000 | DFROM-16000 |

| Membrane Per Vessel | 1 | 1 | 1 | 1 | 1 | 1 |

| Membrane Quantity | 1 | 2 | 3 | 4 | 6 | 8 |

| Membrane Size | 4" x 40" (4040) | 4" x 40" (4040) | 4" x 40" (4040) | 4" x 40" (4040) | 4" x 40" (4040) | 4" x 40" (4040) |

| System Dimensions** | DFROM-2000 | DFROM-4000 | DFROM-6000 | DFROM-8000 | DFROM-12000 | DFROM-16000 |

| L x W x H inch (cm) | 25" x 25" x 60" (63.5 x 63.5 x 152.4) | 34" x 25" x 60" (86.36 x 63.5 x 152.4) | ||||

| Weight lb. (kg) | 384 | 404 | 424 | 444 | 526 | 546 |

| Operating Limits | ||||||

| Maximum Feed Temperature °F (°C) | 105 (40.96) | |||||

| Minimum Feed Temperature °F (°C) | 40 (4.44) | |||||

| Maximum Ambient Temperature °F (°C) | 120 (48.89) | |||||

| Minimum Ambient Temperature °F (°C) | 35 (1.66) | |||||

| Maximum Feed Pressure psi (bar) | 85 (5.86) | |||||

| Minimum Feed Pressure psi (bar) | 35 (2.41) | |||||

| Maximum Operating Pressure psi (bar) | 150 (10.34) | |||||

| Maximum SDI Rating | < 3 | |||||

| Maximum Turbidity NTU | 1 | |||||

| Maximum Free Chlorine ppm | 0 | |||||

| Maximum TDS ppm | 2000 | |||||

| Maximum Hardness gpg | < 1 | |||||

| Maximum pH (Continuous) | 11 | |||||

| Minimum pH (Continuous) | 3 | |||||

| Maximum pH (Cleaning 30 Min) | 12 | |||||

| Minimum pH (Cleaning 30 Min) | 2 | |||||

| * Product flow rates are based on equipment test parameters. | ||||||

| ** Does not include operating space requirements. | ||||||

NOTE.

The water industry uses the RO System Production Rating as a standard and it is best suited for “perfect water conditions”, which is rare in any case. An ideal condition is specified as “water less than 2000 ppm TDS (Total Dissolved Solids) with a temperature of 77 degrees F”. If your TDS is dramatically higher or your temperature is dramatically lower, the system production will be greatly impacted.

If your TDS is above 2,000 ppm, or you are in a region where your water temperature is lower or higher than 77 degrees F you should consult with one of our Certified Water Specialists before selecting a system. In certain cases, a pretreatment application may be necessary to achieve your water treatment goals.

Receive our latest updates about our products & promotions.

Thanks for subscribing!

This email has been registered!